Contaminant Mapping

INSIGHT INTO CONTAMINANT MAPPING

Step 1 – Initial Mapping Activity (Noise)

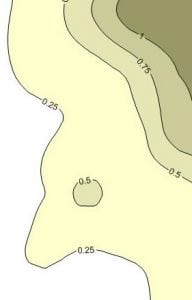

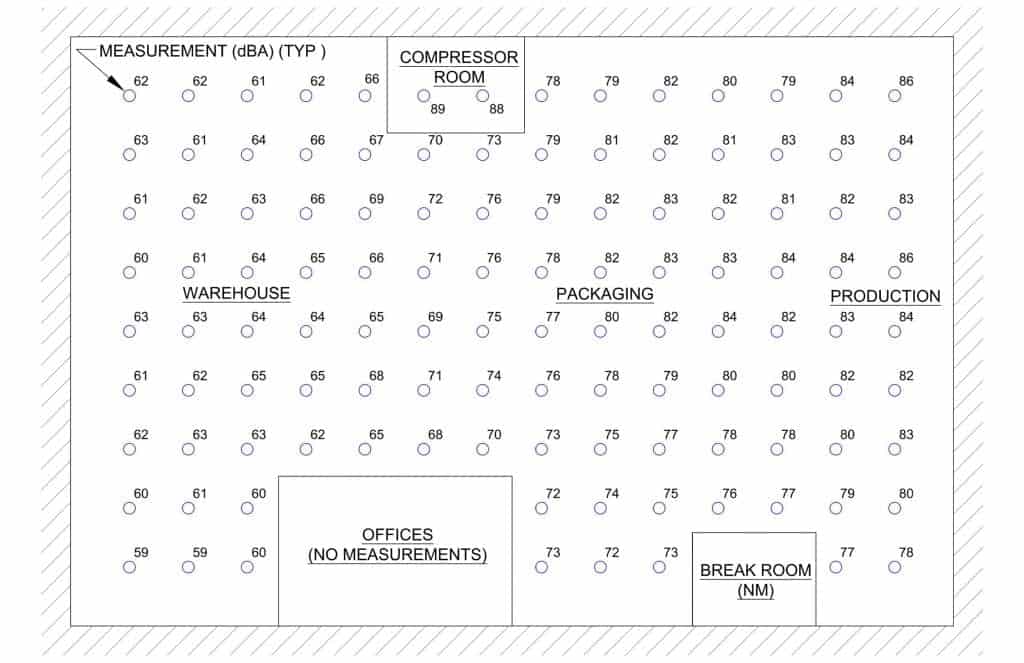

It is ideal to further process the results of the initial survey into a contour map. These maps are easy to communicate to employees and upper management, and are ideal for posting within the workplace. They can identify sources of a contaminant, and in the case of dust and carbon monoxide, even determine air patterns and system balance.

Step 2 – Contour Mapping of Measured Noise Levels

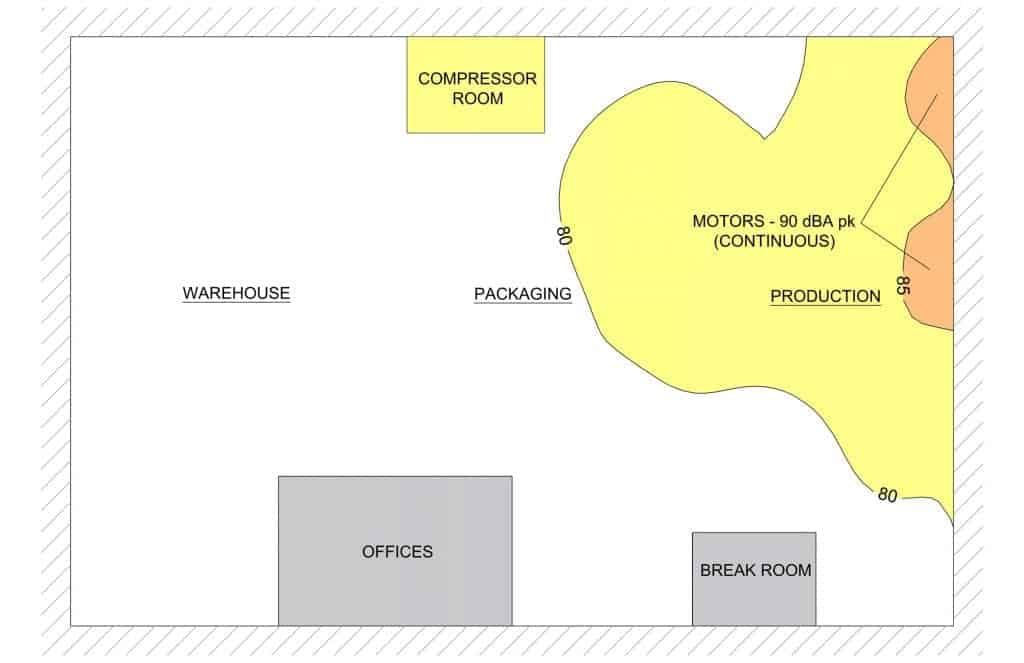

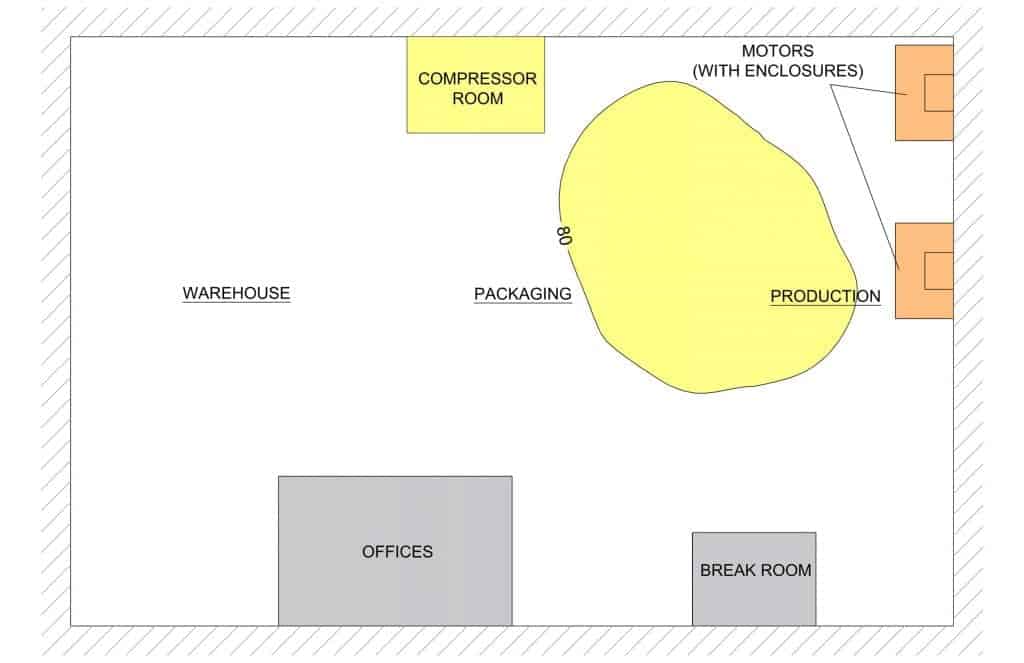

Once sources have been identified, potential engineering controls can be deployed. In this fictional example, enclosures were placed around the highest identified noise sources (the motors). A follow-up map showed the effect of the engineering change, as half of the workplace that had earlier exceeded 80 dBA was now below that threshold, and the noise exceeding 85 dBA was mitigated from floor employees. The end result was that the majority of employees that exceeded 85 dBA over a full-shift was greatly reduced. Employees can now communicate more easily, the need for annual audiometric tests is reduced, and with further modifications (targeting the remaining contour in Production/Packaging), it may be possible to further reduce the noise levels within the facilities.

Step 4 – Follow-up Noise Map (After Step 3 – Engineering Controls)