Ventilation is inherently linked to personal breathing zone concentrations of contaminants. These engineering controls are quite costly to deploy, so in nearly all cases, the presence of such equipment suggests the potential for high exposures. Unfortunately, often maintenance of such equipment is neglected, either through lack of time or expertise.

A typical ventilation system is composed of five components (moving from the employee backwards):

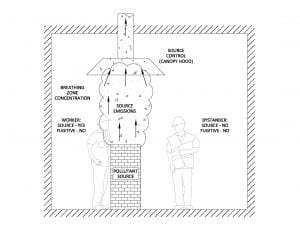

Hood – This is the device that delivers the pressure differential to the employee, and is often shaped/oriented to provide the best protections. For a large dip tank, this would be a slotted hood, capable of providing a uniform airflow a desired distance from the hood, whereas in a laboratory setting, the hood would include a sash for splash protection and monitored inflows to ensure that created airborne contaminants cannot escape the enclosed hood. Issues that could compromise hood designs include:

- Improper Selection – A canopy is a poor choice for a high particulate generating grinding operation. Similarly, a normal hood may be deployed in an application that would be better suited for a slotted hood. Often systems are re-purposed from one work activity to another, without consideration of their ultimate effectiveness.

- Damage Hoods – Systems often incur damage through normal industrial activities over time. If these are not repaired, then system effectiveness can suffer. Missing slats can greatly increase the open area of hoods. The removal of a supply system on a pickling tank could have pronounced effects, depending on its contents/size.

- Employee Modifications – The ability to adjust a ventilation system can often be a curse, as employees often will close dampers/gates, aim supply systems away from their station, or de-activate the system altogether due to discomfort (temperature, noise, etc.) or effects on production (welding quality, loss of chemical in a dip tank).

Ductwork – This is the means of transporting exhaust from the generation point to the employee. Most often this is of circular/steel construction, but depending on applications it can be oval/rectangular and constructed of plastic or other materials. Common issues observed with duct work include:

- Improper Sizing – Ventilation branches are often changed over time to meet production modifications. When such changes occur, the balance of the entire system can be compromised.

- Open Ducts – Equipment can be taken out of service, and the associated duct work remains, and often not blanked. This can impact flow rates throughout the system.

- Damage – Round duct that has been collapsed or dented reduces the available flows. Holes and rust can rob airflow before it can reach the hood.

- Settling – With improper transport velocities, particulate can settle out on interior surfaces of the duct, reducing the cross-sectional area and potentially the flow.

Collector – There are a multitude of means to separate the particulate/contaminant from the captured air stream, including fabric bags (baghouses), pleated high area filters (cartridge collectors), chemical reaction/slurry (scrubbers), electrostatic charges (electrostatic precipitators), combustion (thermal oxidizers/flares/afterburners), etc. Considerations for collection equipment include:

- Clogged and Damaged Filters – Media requires routine changing/cleaning, and improper maintenance can mean the exhaust system is performing underneath design rates.

- Lack of Instrumentation – Magnehelic gages and other readouts allow for maintenance to quickly ascertain the need for media changes. Missing or damaged instrumentation typically points to a lack of proper maintenance.

Fan/Blower – This is the means of creating a differential pressure at the hood and across the media to move contaminant laden air from the source to the treatment location. Most often these devices will be belt or direct-drive centrifugal fans (blowers), but also includes such devices as in-line fans, axial-type fans, etc. An improperly functioning blower could be a result of one of the following issues:

- Slipping Belt(s) – Belt-driven fans are powered through belt which connects the fan to a motor. These belts age and stretch over time, a process that is hastened when exposed to the elements (such as on a facility roof). Improper tension on the belt can result in slippage, which will reduce the overall RPMs of the fan (and thus negatively impact its generated air flow).

- Worn Motors – Most fans/blowers are driven by motors. These have a finite service life that can end with decreased operations, that will subsequently reduce fan rotation and air flows.

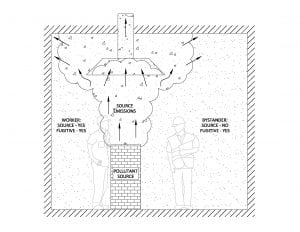

Supply Air – This is often over-looked in ventilation systems. Supply air is fresh air that is introduced at a location where exhaust air is being removed. Without this replacement, a facility can develop a significant negative pressure (noticeable when man-doors are difficult to open) which can greatly reduce the efficiency of control systems. Locations with improper supply air introduction can develop the following symptoms.

- The “Sump Effect” – Airborne contaminants from the surrounding work areas all exit the facility at the same exhaust point, due to a substantial negative pressure. Often seen as an issue with paint booths and other high flow devices.

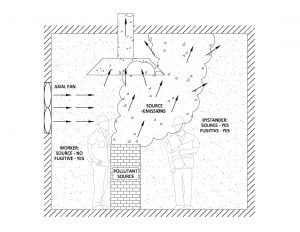

- Axial Fans – These devices are a cost-effective (and often critical) means of handling temperature concerns and addressing heat stress and fatigue. Improper placement of these devices can greatly disrupt the capture efficiencies of neighboring control equipment. Further, axial fans rarely blow clean air, just “cooler” air.

- Stagnant Areas – Air exhibiting little movement is of great concern in industrial environments, as generated contaminants can build and linger in the air for an extended duration of time.

These are but a few of the commonly observed deficiencies noted within industrial ventilation systems. Often problems with worker exposures and indoor air concentrations are a result of a number of these factors working in concert with one another. Ventilation systems are costly to install and operated. Be sure that your system is working exactly as it should.

Insight IH Consulting is experienced in working with a multitude of ventilation systems. We have staff that have been schooled in Mechanical Engineering, with experience in ventilation assessment and design.

Insight IH Consulting is experienced in working with a multitude of ventilation systems. We have staff that have been schooled in Mechanical Engineering, with experience in ventilation assessment and design.